RTP vs. PCAP

10.08.2023 // R. Helfenstein

From taboo to absolute must-have

The slightly older readers will surely remember: just 15 years ago, it was an absolute taboo to even touch a display surface with your fingers. However, the way applications are operated through touch on the display surface has fundamentally changed since then. This can be well observed at our trade show appearances: Nowadays, users expect something to happen when they press a display. If nothing happens, the user's first reflexive question is whether the display is faulty.

And then came..the PCAP technology

This behavior was changed by the first iPhone launched by Apple in 2007. It allowed the masses for the first time to operate an application through gesture control on the display surface. This was made possible by the PCAP technology (Projected Capacitive Touch), which detects multiple touches on the display surface simultaneously. The author of this article considers this invention to be a "fundamental innovation" in the display field. However, it should not be forgotten that there were already applications with touch screens before the iPhone: Most of us have probably programmed portable navigation systems that are ideally operated with a stylus. These displays are mostly equipped with an RTP (Resistive Touch Panel).

But what are the advantages and disadvantages of these two technologies? Does RTP still have a place in today's world, or is it foreseeable that PCAP will completely replace this technology?

1. RTP

Structure

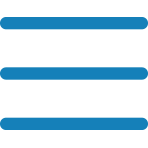

In an RTP, two unilaterally conductive coated layers (glass substrate / plastic top layer) are placed at a defined distance from each other. When pressure is applied to the top layer, the two conductive layers come into contact (touch event). By measuring resistance in horizontal and vertical directions, the position of the touch event can be determined.

1. Glass substrate 2. Conductive ITO layer 3. Spacer 4. Plastic surface with ITO layer

Pros

- Since a touch event is triggered only by mechanical pressure, RTP is immune to electrical interference and liquid on the touch surface.

- It can be operated with any type of gloves or stylus.

- The control is comparatively simple.

Cons

- Only individual touch events can be detected, so gestures like zooming with two fingers are not possible.

- The plastic surface of the touch panel is relatively prone to scratches.

- Visibility is limited under direct sunlight due to the additional air gap.

- Being an analog input device that changes characteristics through wear, it requires regular calibration.

2. PCAP

Structure

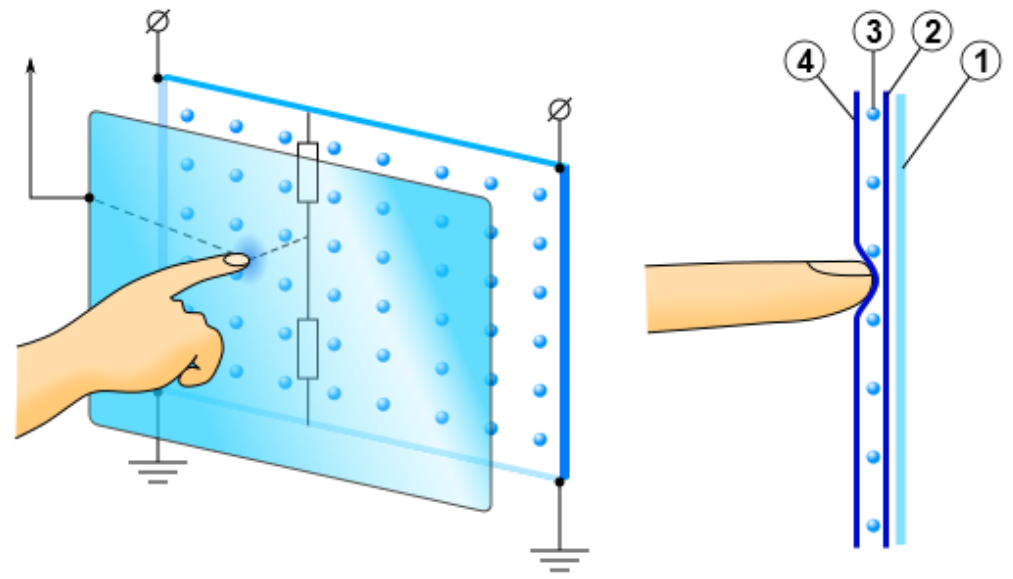

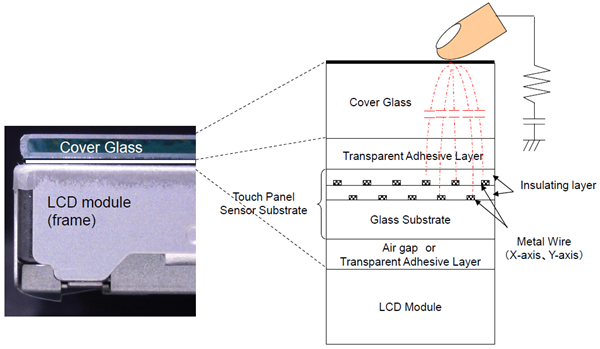

In a PCAP, horizontal and vertical transparent lines are arranged in a matrix structure, and with a touch controller, electric fields are established between the intersection points. These fields are disrupted by conductive objects (e.g., fingers), and the control electronics can determine the positions of the disruptions, which are registered as "touch events."

Source: PCAP Application Note / MITSUBISHI ELECTRIC CORP / January 13, 2014

Pros

- Multiple touch events can be detected simultaneously, enabling gesture controls.

- Since the position of the electric fields is fixed and there's no wear, no calibration is necessary.

- A PCAP can be optically bonded to the display, improving visibility under direct sunlight.

- Since the top layer is made of glass, the surface is very robust, allowing for vandal-resistant solutions with sufficiently thick glass.

Cons

- Electrical interference can lead to incorrectly recognized touch events.

- Operation is only possible with conductive objects (e.g., fingers or conductive styluses); thicker gloves or prosthetics are not suitable for input.

Conclusion

For the vast majority of use cases, input systems based on PCAP technology are implemented today; the technology has matured over the years. Regardless, there will continue to be areas of application in safety-sensitive fields where RTP technology is more suitable.

As your partner, we're here to advise you and help you make the right decision for your project.

We look forward to hearing from you!