Balanced parameters for TFT-displays

13.11.2020 / C. Zhao

The starting point

For outdoor applications, usually TFT modules with high brightness are taken into account - especially if the power consumption is not a critical point. However, solutions with low power consumption such as transflective or reflective TFT displays do not achieve the same level of performance in terms of contrast and color vividness compared to transmissive TFT displays.

Lifetime

At the same time, the lifetime of the display should at least be the same as the lifetime of the customer application – which can vary between 50,000 and 100,000 hours. The lifetime of a display is specified as the time at which the module brightness drops to 50% of the original brightness. This does not mean that the display definitely loses functionality, but rather reduces its functionality. LEDs are usually used as the lighting method - these are also a critical part with regard to the lifetime of a TFT module.

Heat and temperature LED

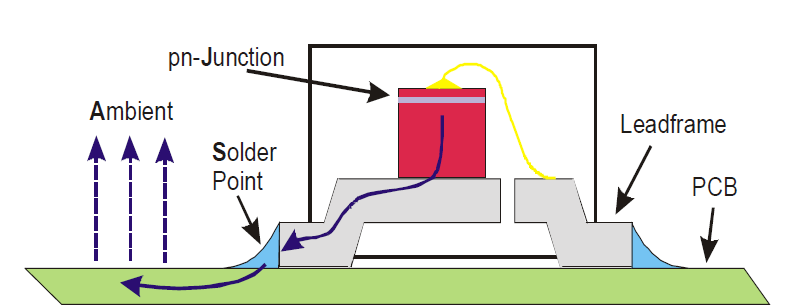

can’t convert all the energy to visible light. A part of the energy will be wasted as heat. How to get higher luminous efficiency LED is always a very import topic for the LED industry. When the LED works at a higher temperature generated by the heat, the lifetime of the backlight will be reduced. For a better design, heat should be dissipated through an efficient path to the ambient (like below). Why is that so?

The semiconductor material (silicon) that belongs to LEDs is doped with various substances. These substances vibrate at high temperatures and can thus be thrown out of the semiconductor material. The throwing out of the substances is part of the fact that the light power is decreased and the light color changes. LEDs (and thus also TFTs) should therefore not be stored outside of the operating and storage temperatures that are specified by the supplier.

Heat Dissipation

(Source: Osram)

Technics Heat dissipation path: Here a practice is carried out to find out how the heat dissipation path affects the temperature. As shown below: Case "1" is the LED backlight with 2.155W power consumption for a 7-inch-high brightness TFT module. The LEDs are soldered to the FPC and assembled to the main metal frame.

Case "2" is the LED backlight with similar 2.1W power consumption also for a 7-inch-high brightness TFT module. The LEDs are soldered to a long thin strip PCB and have no direct contact to the metal frame. The temperature of LEDs and the metal frame as a heat sink are measured separately for case "1" and case "2" at ambient temperature of 20°C as below:

Case "1" shows a temperature difference between LED to the frame of about 3.2 °C. In contrast, case "2" shows a temperature difference between LED and the frame of about 15 °C. It shows that case "1" has a much higher heat dissipation efficiency. The temperature of the metal frame is quite similar, max 35.0 °C for case "1" vs. max 36.1°C for case "2". But the LED works at a temperature of 38.2°C for case "1" vs. at a temperature of 51.1°C for case "2". If the LED of case "2" could work at same temperature as the LED of case 1, means 12.9 °C lower, the lifetime could double[1].

Dimming

Due to different lighting conditions (for example on a sunny day the outdoor illuminance can be more than ten thousand Lux, whereas a dark cloudy day may only reach an illumincance of a few hundred Lux) the brightness of a TFT does not always need to reach the maximum brightness level. A light sensor integrated into the system or display to adapt the brightness of the display will help to increase the display lifetime and reduce the power consumption as well.

Transmission of the TFT cell

Besides the above discussion for the LED backlight, the transmission ratio of the TFT panel also plays a big role. We specify the pixel density for TFT displays with PPI (pixel per inch). The higher the PPI value, the lower the aperture ratio and the lower the panel transmission ratio accordingly. By using LTPS (Low-temperature polycrystalline silicon) TFT technology rather than a-Si (Amorphous silicon) TFT, the aperture ratio can be improved.

Some displays data are collected and a diagram is shown as followed. The trend indicates how the transmission ratio of the TFT panel reduces depending on the increasing of PPI value.

For applications such as virtual reality headsets, the PPI of the display is much more crucial. There have been displays introduced to the market with over 3000 PPI. Normally the naked eye is not able to distinguish a PPI over 200 at a watching distance of over half a meter. A TFT display with 128 PPI has about 35% more transmission efficiency than a TFT display with 217 PPI. Therefore it is not always a good idea to use an unnecessarily high resolution as this will reduce the lifetime of the backlight accordingly.

If you would like to know more about balancing the parameters for an optimized display solution – get in contact with us! We'd be pleased to share our ideas with you.